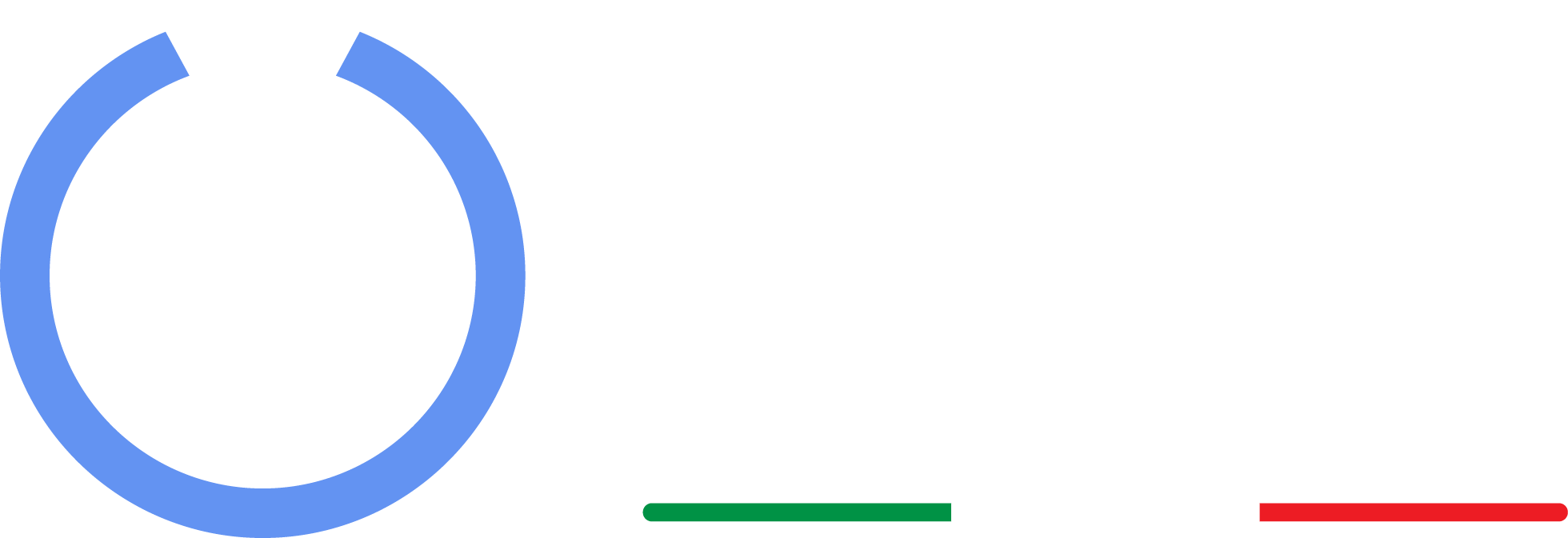

HDF - Horizontal Distributor Feeder

TecnoBilance

The Horizontal Distributor Feeder HDF by Tecnobilance represents the ideal solution for the precise and continuous distribution of powdered or granular products along two distinct discharge lines, ensuring high flow homogeneity and operational reliability even in harsh industrial environments.

Designed with the goal of maximizing efficiency, safety, and durability, the HDF is entirely made of painted or stainless steel, with a compact structure, robust motorization, and high-quality components, and complies with Machinery Directive 2006/42/EC.

Operation

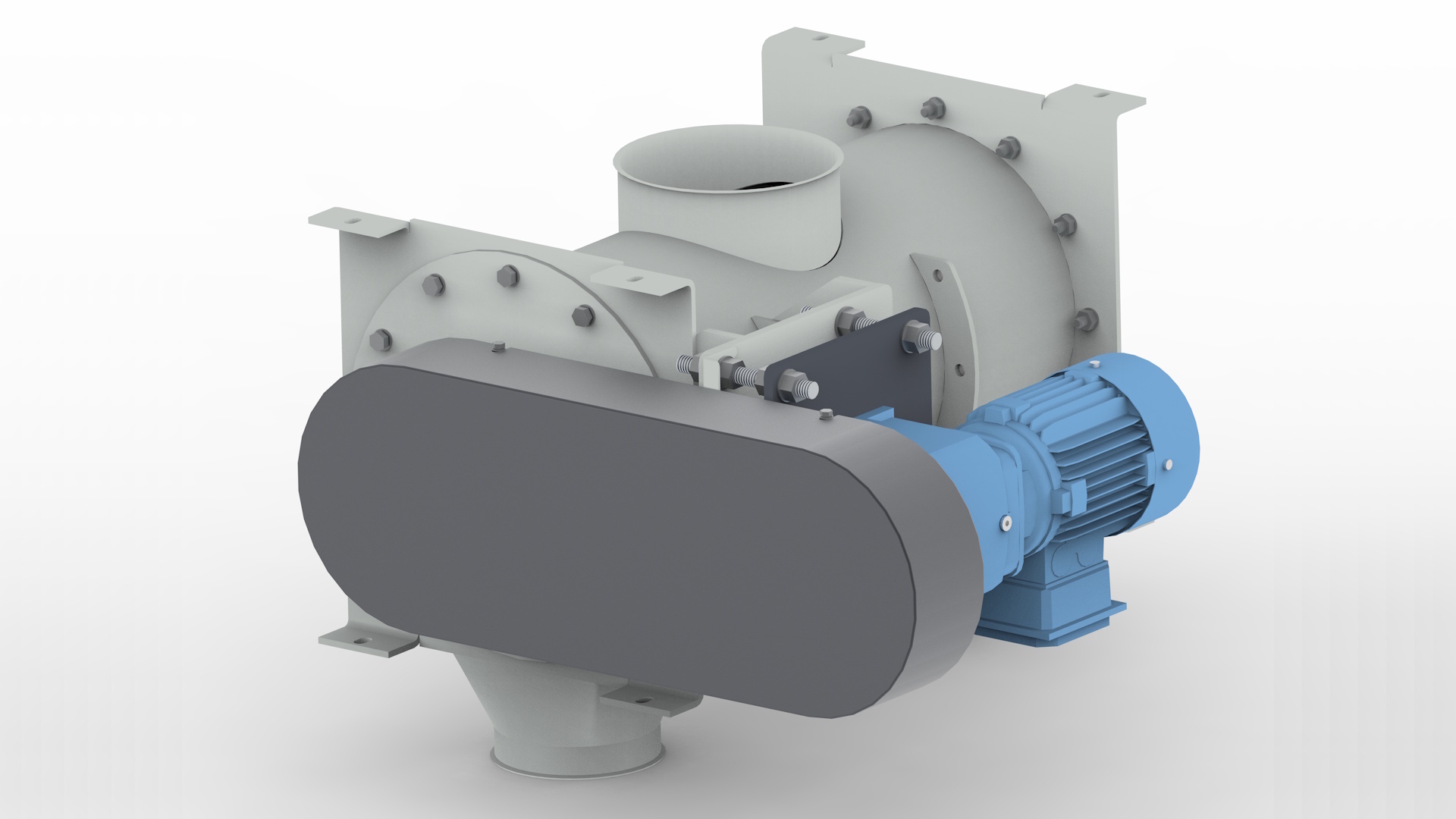

The product is fed in from above and conveyed, via a screw conveyor with opposing flights (right and left), towards two lateral discharge outlets. It is particularly suitable for food lines, feed mills, flour mills, and agro-industrial plants.

Key Features

- Symmetric or adjustable flow distribution between the two outlets.

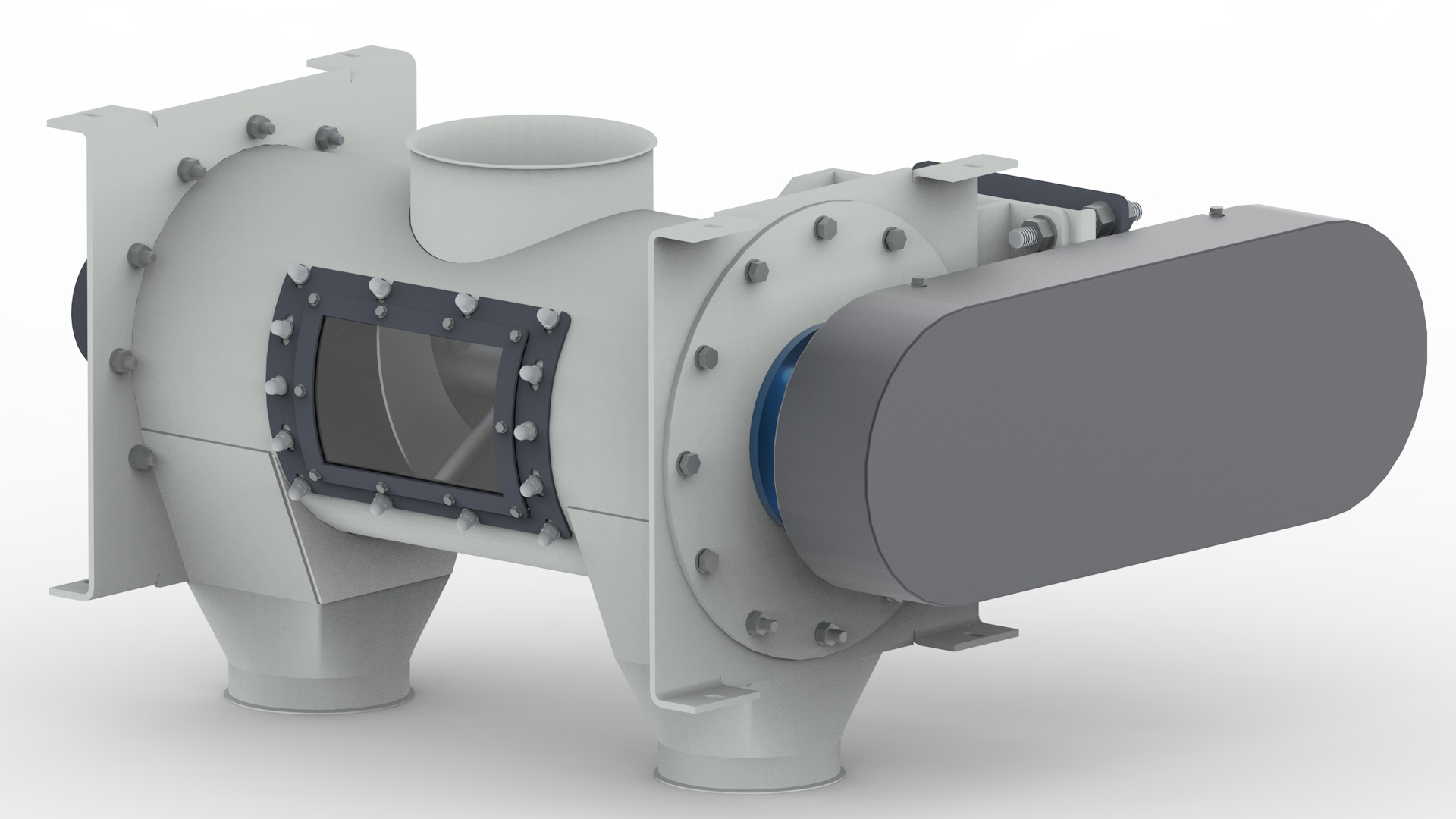

- Horizontal axis motor or gearmotor (direct mounting or with chain drive).

- Double opposing flight screw mounted on SKF bearings with reinforced seals.

- Sound level below 70 dB(A).

- Mechanical adjustment of distribution via shaft translation.

- Completely enclosed structure, designed for in-line connection with other machinery.

Simplified Maintenance

- Quick inspection and cleaning thanks to the easily removable cover.

- Accessible grease nipples for periodic lubrication.

- Inspectable and adjustable transmission chain.

- Reducer and selected components for reduced maintenance.

Safety

- Compliant with CE regulations

- Protections on all moving parts

- Safety labeling

Typical Applications

- Wheat and rice mills

- Dosing or bagging stations

- Pneumatic conveying lines

- Silo and hopper feeding systems

* Flow rates can vary based on the product being processed (density, flowability) and the inclination of the machine body.

Products

Single Hopper Scale

01Single Hopper Scale V2

02Double Hopper Scale

03Micro Hopper Scale

04Loss Weight Feeder

05Flow Balance Machine

06Micro Dosing Feeder

07Simple Micro Doser

08Screw Conveyor Feeder

09Automatic Dampening Machine

10Intensive Screw Conveyor

11Pelican Sampler

12High Pressure Rectangulat Filter

13Horizontal Distributor Feeder

14Big Bag Filler

15Fluting & Grinding Machine

16Sand Blasting Machine

17Laser Aided Profiler

18* Flow rates can vary based on the product being processed (density, flowability) and the inclination of the machine body.